Did you know dual extrusion 3D printers range dramatically in price from $400 for the Flashforge Creator Pro 2 to nearly $12,000 for professional models like the BCN3D EPSILON W50 SC?

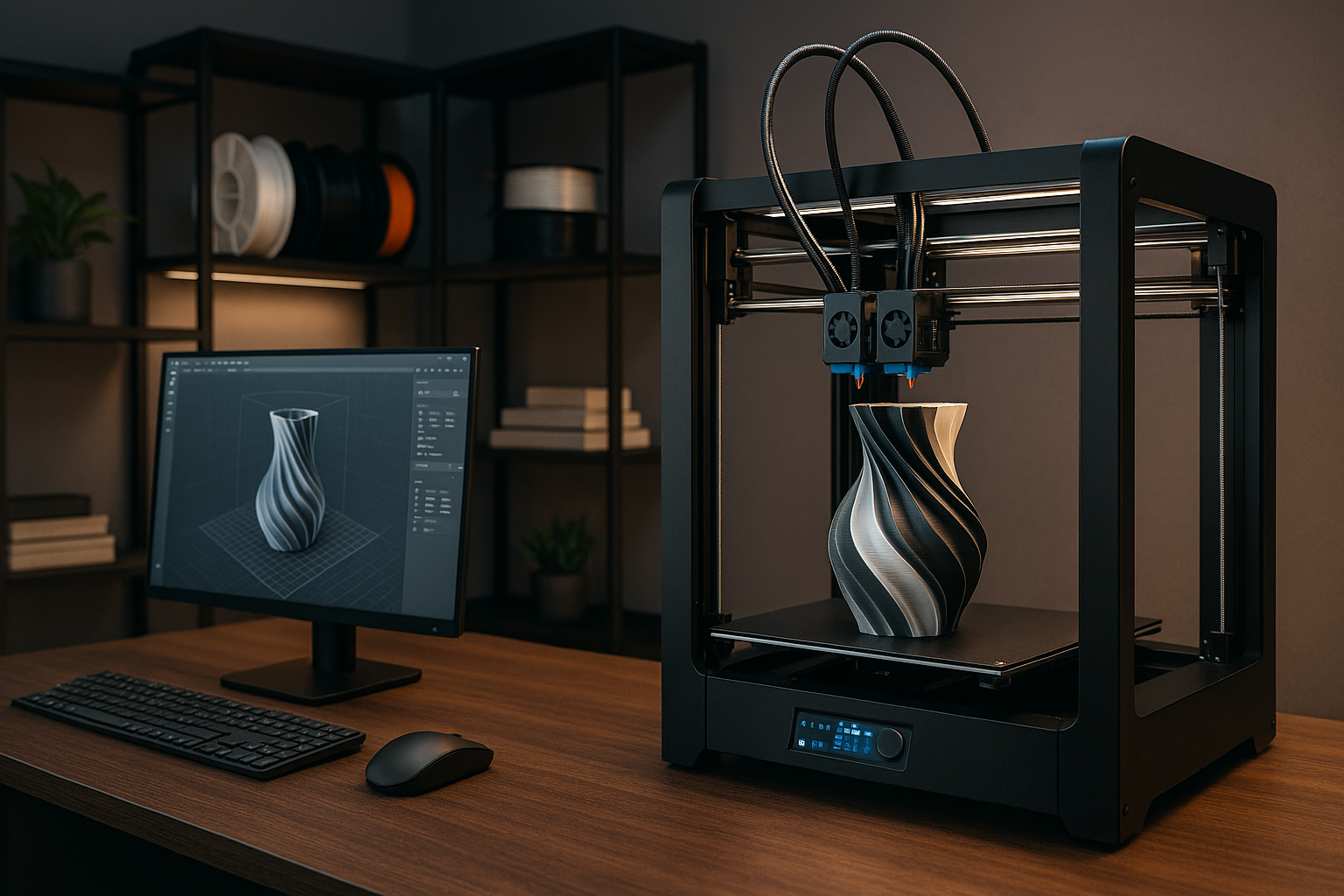

These versatile machines offer capabilities impossible with standard 3D printers. Unlike traditional single extruder models, the best dual extruder 3D printers can combine different materials with contrasting properties, such as rigid and flexible plastics, in a single print. Additionally, dual extrusion allows for vibrant multi-color printing without extensive post-processing. Independent dual extruders (IDEX) can even operate in duplication mode, printing two identical objects simultaneously, doubling your production capacity.

When searching for 3D printer extruder services, understanding these capabilities becomes essential for your specific project needs. This guide examines top-rated digital agencies offering multi-extruder 3D printer services. It helps you identify which provider best matches your requirements.

Understanding Dual Extruder 3D Printing Services

“Dual extrusion, which uses two independent nozzles to deposit filament within the same print, introduced the capability to print with multiple materials in one operation, allowing for greater design versatility and complexity.” Ultimaker, a Professional 3D printer manufacturer

Dual extruder 3D printers have fundamentally altered the 3D printing landscape by expanding manufacturing capabilities beyond what traditional single-nozzle systems can achieve. These specialized machines feature two extruders, each capable of printing with different filament materials, creating possibilities that would otherwise require multiple printing sessions or extensive post-processing.

1. What is a dual extruder 3D printer?

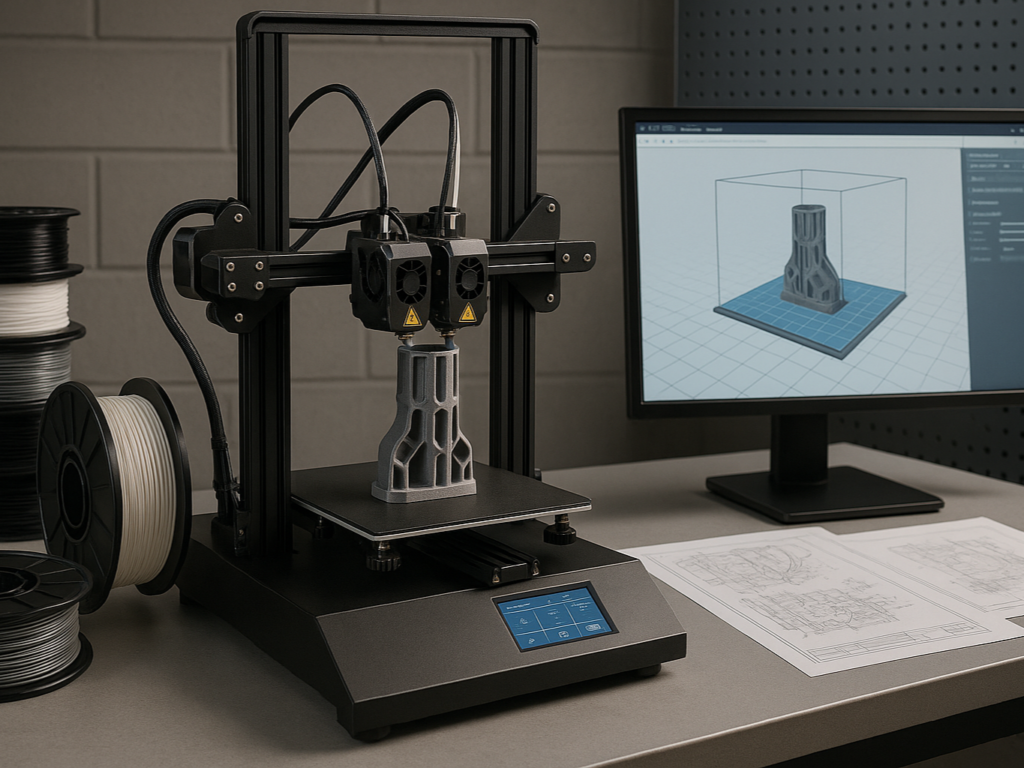

A dual extruder 3D printer is an FDM-type (Fused Deposition Modeling) machine with two separate extruders with different filament materials. Depending on the configuration, these extruders can work in unison or independently.

Two primary types exist in the market:

- Dependent Dual Extruders: In this design, both nozzles remain in contact throughout the printing process, moving together in the same direction. These are sometimes called “contact design” systems. A limitation of some dependent systems is their inability to lift away from the object being printed, potentially causing collisions with the model.

- Independent Dual Extruders (IDEX): These systems allow each extruder to move independently of the other, enabling specialized functions like duplication mode (printing identical objects simultaneously) and mirror mode (printing an object and its inverse concurrently). IDEX systems can also lift away from objects during printing, reducing the risk of damaging the model.

Single-head dual-nozzle setups represent another variation where both nozzles attach to the same print head, moving synchronously. It differs from full IDEX systems, where extruders move completely independently.

2. Benefits of dual extrusion for commercial applications

Dual extruder technology offers numerous advantages for commercial applications:

- Enhanced Productivity: According to BigRep, with IDEX systems, manufacturers can utilize “tandem mode,” which splits the printing platform in half and enables the production of identical parts in half the time, effectively doubling production capacity.

- Material Versatility: Companies can combine rigid plastics with flexible materials to produce functional over-molds in a single print job. Furthermore, by setting different parameters for each extruder in the slicing software, you can complete dual-material printing with optimal settings for each material.

- Structural Optimization: For transportation, automotive, and aerospace industries, dual extrusion enables strategic lightweight, maintaining strength capabilities while creating honeycomb internal structures with lighter plastics.

- Reduced Post-Processing: Dual extruders eliminate the need for time-consuming manual painting when creating multi-color objects. Moreover, complex geometries require significantly less finishing work using specialized support materials.

- Increased Reliability: In some setups, if one extruder fails or clogs during printing, the idle extruder can take over, improving overall uptime and reducing failed prints.

3. Common use cases: multi-color, soluble supports, and functional parts

The practical applications of dual extruder printing span multiple industries:

Multi-Color Production: Unlike traditional multi-color machines that use filament-changing or filament-blending techniques, dual extruder printers utilize two completely different filaments, creating vibrant color combinations with minimal post-processing. This capability is valuable for color-coded safety fixtures on assembly lines, diagram models for healthcare communications, and educational or artistic purposes.

Soluble Support Structures: The most compelling use case involves combining model materials with dissolvable supports. Common combinations include:

- PLA with PVA (water-soluble polyvinyl alcohol)

- ABS with HIPS (dissolves in limonene)

- Various materials with BVOH (butene diol vinyl alcohol copolymer)

Highlighted by 3Dnatives, for intricate designs with internal cavities or complex geometries, these soluble supports dissolve completely after printing, leaving pristine surfaces that would be impossible to achieve with traditional supports. This represents a newer alternative that dissolves twice as fast as PVA at room temperature and up to six times faster in heated water.

Functional Material Combinations: Dual extruders excel at creating parts with varied mechanical properties:

- Combining rigid PLA with flexible TPU for parts requiring both firmness and elasticity

- Pairing standard materials with specialized reinforcements for targeted strength

- Using different nozzle sizes simultaneously, smaller for fine details, larger for structural components

These capabilities empower manufacturers to create complex, functional prototypes and end-use parts that previously required assembly of multiple components or weren’t feasible.

Types of Dual Extruder 3D Printer Technologies Offered by Agencies

When selecting a service provider for complex 3D printing projects, understanding the different dual extruder technologies they offer becomes crucial for matching capabilities to your specific requirements. Digital agencies specializing in 3D printing services typically operate with four distinct dual extruder technologies, each with unique advantages for specific applications.

1. Independent Dual Extrusion (IDEX) for parallel printing

IDEX represents the most advanced dual extrusion technology available in the market today. Unlike conventional setups, IDEX features two separate print heads that move independently along the X-axis. This independence creates several distinct advantages:

- Minimal contamination: The idle extruder parks away from the print area, eliminating oozing contamination and collision issues with the active extruder.

- Parallel printing capabilities: IDEX systems can operate in duplication mode (printing identical objects) or mirror mode (simultaneously printing mirrored versions), doubling production capacity.

- Enhanced accuracy: With lighter individual extruder carriages compared to mechanically linked systems, IDEX printers achieve faster movements with higher accuracy.

Despite these benefits, IDEX technology presents certain challenges. The precise alignment between independent extruders requires tight manufacturing tolerances, making calibration between the two extruders in the X, Y, and Z axes particularly demanding. Consequently, IDEX-equipped agencies typically charge premium rates due to the higher hardware costs and engineering expertise required.

2. Single-nozzle multi-material systems with purge towers

Many agencies offer single-nozzle multi-material services as a cost-effective alternative to full IDEX systems. These printers utilize a separate filament-changing mechanism that feeds multiple materials through a single nozzle.

The primary challenge with this approach is filament contamination. To address this issue, these systems employ “purge towers” – sacrificial structures printed alongside the main model that purge the previous material before introducing a new one. Explained by The SMuF, although functional, purge towers create significant material waste, potentially using as much as 34,860 mm³ of filament for a standard 249-layer model.

Some agencies have begun adopting innovative solutions like the Programmable Filament method, where operators pre-print a custom filament with material transitions precisely positioned for the intended model, reducing waste by minimizing the number of required exchanges.

3. Tool changer systems for high-end material flexibility

For projects demanding maximum versatility, certain specialized agencies offer tool changer-based systems. Rather than switching filaments, these printers change entire tool heads mid-print.

Noted by Review: E3D Motion System, the E3D Motion System exemplifies this approach, featuring four swappable tool heads that combine different functional capabilities, including various extrusion printheads, laser engravers, and CNC tools. Tool changer systems provide unmatched component customization within a single print job.

Several agencies have begun offering ProForge 300 Tool Changer services, which utilize three print heads without requiring purging or material waste between changes. This makes it a powerful alternative to a dual extruder 3D printer for complex, multi-material applications.

4. Dependent dual-nozzle systems and their limitations

The most economical dual extrusion option remains dependent on dual-nozzle systems where both extruders share the same carriage, moving in unison. While more affordable than IDEX alternatives, these systems suffer from several limitations:

Idle nozzle dripping remains a significant challenge, as material from the inactive nozzle may leak onto the print surface. Some advanced implementations incorporate lifting mechanisms that raise the inactive nozzle by 1.5mm when not in use.

Despite these challenges, dependent systems offer certain advantages for specific applications, particularly dual-color or multi-material printing without excessive filament waste. For straightforward projects that don’t require parallel printing or complex material combinations, these systems provide a cost-effective solution that many agencies continue to offer.

Top-Rated Digital Agencies Specializing in Dual Extruder 3D Printing

Several specialized agencies have emerged as leaders in the dual extruder 3D printing space, each offering unique advantages for different project requirements. From rapid prototyping to high-volume production, these companies provide cutting-edge capabilities to meet diverse manufacturing needs.

1. Creative 3D Technologies: Expertise in IDEX-based prototyping

Creative 3D Technologies is a leading U.S.-based 3D printing agency known for innovation and precision. With a focus on dual extruder 3D printing, they deliver high-performance prototypes and end-use parts using advanced multi-material technology for businesses across various industries.

This agency blends engineering expertise with state-of-the-art hardware to meet demanding project requirements. They’re recognized for their responsive customer service, professional design support, and consistent print quality, making them a go-to choice for startups, inventors, and enterprise clients needing reliable 3D solutions.

Website: Creative 3D Technologies

(i) Specialization in Dual Extruder Printing

Creative 3D Technologies specializes in dual extrusion for multi-color and multi-material parts, offering precise interlocking component printing. They utilize machines like the Raise3D Pro3 and Prusa i3 MK3 to achieve durable, functional prototypes with soluble support materials.

(ii) Services Offered

- Dual-material and multi-color 3D printing

- CAD design and file optimization

- Functional prototyping and small-batch manufacturing

- Post-processing and finishing

- Material consultation and support

(iii) Supported Industries

- Automotive & Transportation

- Consumer Electronics

- Medical Devices & Healthcare

- Aerospace & Robotics

- Education & Research

(iv) Brands They’ve Worked With

Creative 3D Technologies has partnered with notable brands, including Bosch, Harvard Medical School, and Snap-on Tools, providing specialized 3D solutions tailored to each sector’s unique needs.

(v) Why They’re Recommended

Creative 3D Technologies stands out for its expertise in dual extruder 3D printer applications, technical consulting, and rapid turnaround times. Their ability to handle complex geometries and functional prototyping makes them ideal for engineering teams and product designers seeking precision and speed. Trusted by top brands, they’re a reliable partner in 3D innovation.

2. E3D: Specialization in tool changer-based production

E3D is a globally recognized digital manufacturing company specializing in advanced 3D printing solutions, particularly in the Dual Extruder 3D Printer segment. Their dual extrusion services deliver highly detailed, multi-material prints with superior precision, serving industries that require innovation and top-tier performance.

Known for pushing the boundaries of 3D printing technology, E3D combines proprietary hardware with expert technical support. Their services help startups and enterprises optimize product development cycles, reduce prototyping costs, and accelerate time to market with superior dual extrusion capabilities.

Website: E3D

(i) Specialization in Dual Extruder Printing

E3D focuses on dual extrusion systems, allowing complex multi-material and multi-color 3D prints. Their expertise includes printing with soluble supports and flexible filaments, ensuring intricate designs with functional durability and seamless layer bonding.

(ii) Services Offered

- Dual extruder 3D printing and prototyping

- Custom tool head and hardware solutions

- Material testing and consultation

- CAD design assistance and file preparation

- Post-processing and finishing options

(iii) Supported Industries

- Aerospace & Defense

- Medical and Dental

- Automotive & Engineering

- Consumer Products

- Education and Research

(iv) Brands They’ve Worked With

E3D has collaborated with leading companies such as NASA, Philips, and Ford, delivering precision 3D printing services that support critical innovation projects worldwide.

(v) Why They’re Recommended

E3D is praised for its innovation-driven approach, reliable dual extruder hardware, and customized printing solutions. Their deep technical expertise and collaborative service model make them the perfect partner for organizations needing advanced multi-material 3D printing with consistent quality and support.

3. Forecast 3D: Affordable multi-color printing services

Forecast 3D offers cost-effective, high-quality 3D printing services specializing in multi-color and multi-material prints. Their user-friendly platform connects clients with top-tier dual extruder 3D printers, delivering vibrant, precise models for prototypes and production parts.

With quick turnaround times and scalable solutions, Forecast 3D supports designers and businesses of all sizes. Their dedication to affordability without compromising quality makes them popular for startups, educators, and product developers seeking multi-color 3D printing.

Website: Forecast 3D

(i) Specialization in Dual Extruder Printing:

Forecast 3D excels in dual extrusion technology for producing multi-color, multi-material 3D prints. They leverage advanced printers that combine vibrant colors and complex geometries with soluble supports for clean finishes.

(ii) Services Offered

- Multi-color and multi-material 3D printing

- Rapid prototyping and short-run manufacturing

- File checking and design optimization

- Post-processing, including sanding and painting

- Online quoting and project tracking

(iii) Supported Industries

- Consumer Goods

- Architecture and Design

- Education

- Healthcare and Medical Devices

- Electronics and Gadgets

(iv) Brands They’ve Worked With

Forecast 3D has worked with notable companies like Hasbro, Stanford University, and Bose, providing accessible multi-color 3D printing services tailored to diverse project needs.

(v) Why They’re Recommended

Forecast 3D is recommended for affordable, reliable multi-color 3D printing with dual extrusion. Their seamless online service, fast delivery, and attention to detail make them an excellent choice for anyone needing vibrant, high-quality prints without breaking the bank.

4. BigRep: High-volume industrial-grade dual extrusion

BigRep is a leader in large-format, industrial-grade 3D printing, specializing in high-volume dual extrusion solutions. Their technology enables the production of sizable, complex parts with multi-material capabilities, which is ideal for industries requiring robust and precise manufacturing.

Combining innovation with scalability, BigRep offers reliable dual-extruder printers designed for demanding production environments. Their systems support functional prototypes, tooling, and end-use parts, helping manufacturers accelerate product development and reduce costs.

Website: BigRep

(i) Specialization in Dual Extruder Printing:

BigRep specializes in dual extrusion for large-scale, multi-material prints with strong layer adhesion and durability. Their printers support advanced materials and soluble supports, enabling complex geometries and high-strength parts for industrial use.

(ii) Services Offered

- Large-format dual extruder 3D printing

- Industrial prototyping and manufacturing

- Material consultation and testing

- Custom part production and batch runs.

- Training and technical support

(iii) Supported Industries

- Automotive

- Aerospace

- Industrial Manufacturing

- Architecture and Construction

- Consumer Products

(iv) Brands They’ve Worked With:

BigRep has partnered with industry giants such as Volkswagen, Boeing, and Siemens, delivering high-quality industrial-grade 3D printing solutions for complex manufacturing needs.

(v) Why They’re Recommended

BigRep is recommended for businesses needing a reliable, industrial-scale dual extruder 3D printer solution. Their large-format machines, expert support, and proven industry collaborations make them a top choice for high-volume production with multi-material precision and mechanical strength.

5. Toner Plastics: Custom material development and testing

Toner Plastics is a U.S.-based manufacturer specializing in high-quality 3D printing filaments and comprehensive plastic manufacturing services. They offer a range of materials, including PLA, ABS, PETG, TPU, and ASA, catering to diverse industrial applications.

With decades of experience, Toner Plastics provides custom solutions through services like filament production, injection molding, and extrusion. Their commitment to quality ensures reliable and cost-effective products for businesses across various sectors.

Website: Toner Plastics

(i) Specialization in Dual Extruder Printing:

While Toner Plastics primarily focuses on filament production, their extensive range of high-quality filaments supports dual extruder 3D printing. Their materials are compatible with dual extrusion setups, enabling complex, multi-material prints.

(ii) Services Offered

- Filament Manufacturing: Production of PLA, ABS, PETG, TPU, ASA, and HIPS filaments.

- Injection Molding: Custom mold design and manufacturing.

- Extrusion Services: Profile extrusion for various applications.

- Tooling & Mold Transfer: Expertise in mold making and transfer.

- Toll Manufacturing: Providing contract manufacturing services.

- 3D Printing & Materials Testing Lab: R&D and testing for material performance.

(iii) Supported Industries

- Medical

- Industrial & Consumer Products

- Point of Purchase

- Toy Hoops

- Crafts

- 3D printing

- Wire & Cable Components

(iv) Brands They’ve Worked With

Toner Plastics has collaborated with various companies across sectors, providing tailored plastic solutions to meet specific industry needs.

(v) Why They’re Recommended

Toner Plastics is recommended for its extensive experience in plastic manufacturing and commitment to quality. Their diverse range of high-quality filaments supports dual extruder 3D printing, enabling complex and multi-material prints. Their comprehensive services make them a reliable partner for businesses seeking innovative plastic solutions.

Key Evaluation Criteria for Choosing a Dual Extruder 3D Printing Partner

Evaluating potential dual extruder 3D printing partners requires focusing on several critical technical factors beyond basic pricing considerations. When comparing service providers, these key criteria will help you determine which agency can best meet your project requirements.

1. Material compatibility and supported filament types

Material compatibility stands as the foundation of successful dual extrusion projects. Top agencies provide compatibility charts for dual extruder systems, detailing which materials work together effectively. For instance, PLA often pairs well with PVA as a water-soluble support. At the same time, ABS works better with HIPS (dissolved using limonene). Importantly, temperature incompatibility between materials represents a major limitation; PLA and ABS cannot typically share a single nozzle due to their vastly different printing temperatures.

When evaluating providers, verify their experience with these common material combinations:

- PLA with PVA for water-soluble supports

- ABS with HIPS for limonene-soluble supports

- TPU with carbon fiber for strength and flexibility

- PETG with nylon for chemical resistance and durability

Request material compatibility charts showing officially supported, experimental, and unsupported combinations for their specific equipment whenever possible.

2. Print resolution and dimensional accuracy benchmarks

Print quality largely depends on dimensional accuracy specifications. Researched by VoxelMatters, generally, industrial dual extruder systems achieve dimensional tolerances between ±0.15% (with a lower limit of ±0.2mm) for FDM printing and ±0.1% (with a lower limit of ±0.05mm) for material jetting. The Pro3 series printers, often used by professional agencies, offer positioning precision under 0.005mm (5 microns).

Beyond raw specifications, look for agencies that provide:

- Layer height capabilities (typically 0.05-0.6mm for professional systems)

- Nozzle size options (0.2mm to 1.0mm affect detail level)

- Documentation of their calibration processes (especially for IDEX systems)

3. Software ecosystem and file preparation support

The software infrastructure supporting dual extrusion is equally crucial. Premium service providers typically utilize advanced slicing software with specific dual extrusion capabilities. For example, the ideaMaker software includes features for handling dual extruder offset calibration, which prevents misalignment between materials.

Ask potential partners about their:

- File preparation assistance for dual-material prints

- Support for dual extrusion wizards that simplify material selection

- Ability to create custom slicing profiles for specific material combinations

- Process for handling material switching and purging waste minimization

4. Turnaround time and scalability of services

Typical projects using a dual-extruder 3D printer require around two weeks for completion, with many agencies offering expedited services. Rush options start within 3 days at a 50% premium, while emergency services (within 8 hours) can cost twice the standard price.

For scalable production, agencies with IDEX systems provide duplication modes that effectively double output, and large-format printers enable batch production, offering economies of scale for smaller parts.

Challenges and Considerations in Outsourcing Dual Extrusion Projects

“The most common way of circumventing this limitation is through automated filament handling technology that switches the filament type fed into the extruder. However, this comes with inherent limitations, as these systems take time to switch between the different materials being fed and waste filament as part of the changing process.” Ultimaker is a professional 3D printer manufacturer.

Outsourcing dual extrusion 3D printer projects introduces technical challenges that require careful consideration before selecting a service provider. Understanding these potential complications helps you avoid costly setbacks and production delays.

1. Cross-contamination risks in single-nozzle systems

Single-nozzle multi-material (SNMM) systems present significant cross-contamination challenges when switching materials. Initially, each filament change requires purging the previous material completely from the nozzle. This process generates substantial waste; a single 500-gram multi-color print can produce over a kilogram of “purge waste.” Hence, projects requiring frequent material changes should factor in this inefficiency when selecting a provider.

2. Calibration and alignment issues in IDEX setups

IDEX printer calibration remains notoriously difficult despite technological advances. Misaligned dual prints are a common issue in IDEX technology, typically stemming from calibration problems in the X and Y axes. Many service providers struggle with maintaining consistent offset relationships between extruders, as positions can shift randomly between print jobs. Correspondingly, some IDEX users report needing to recalibrate after 10 print jobs. Before commissioning work, ask potential partners about their calibration procedures and tolerance guarantees.

3. Cost implications of multi-material purging

The financial impact of material purging extends beyond waste costs. Primarily, multi-color 3D printing without material recycling consideration results in substantial material waste. Given that purge towers for color transitions require extensive purging, material costs can effectively double for complex multi-color prints. Regardless of these challenges, advanced agencies have begun implementing heated vacuum chambers to prepare waste material for recycling.

4. Intellectual property and file security concerns

File security represents a crucial consideration when outsourcing. Digital design files contain sensitive intellectual property that requires protection, especially for defense, aerospace, and healthcare applications. Moreover, hackers can intercept or alter files during transmission, potentially leading to defective parts. In response, leading agencies implement encryption (3076-bit RSA-level) with asymmetric double-key systems and comply with regulations like ISO/IEC 27001 for information security management.

Conclusion

Dual extruder 3D printing is a game-changer in additive manufacturing, allowing for complex designs by combining multiple materials, multi-color printing, and soluble supports that single-nozzle printers cannot match. Selecting the right dual extruder 3D printer service depends on your project’s needs; some agencies specialize in IDEX systems for efficient parallel printing, while others use tool changer setups to enhance material flexibility and minimize contamination.

Material compatibility is key to success in dual extrusion projects. Partnering with experienced agencies that understand your material combinations and follow strict calibration and quality assurance protocols helps ensure precise, reliable results. These experts effectively manage challenges like cross-contamination, purging waste, and maintaining dimensional accuracy, making the complex dual extrusion process smooth and predictable.

As technology advances, top agencies continue to improve precision, expand material options, and boost efficiency. Investing in dual extruder services is often worth the extra cost for projects demanding intricate geometries or multi-material functions, making this technology essential for bridging prototyping and production.