Searching for the best dual-extruder 3D printer has become essential as this technology continues to evolve rapidly, offering significantly enhanced capabilities compared to traditional single-extruder models. 3D printing has come a long way from its early days of basic single-material prints. With the introduction of dual extruder technology, new possibilities have emerged, improving efficiency, design complexity, and material diversity.

One of the most significant advantages of exploring dual extrusion 3D printer options is the ability to combine different materials in a single print. Whether considering the best IDEX 3D printer for professional applications or the best multi-filament 3D printer for complex creative projects, these machines offer game-changing versatility. Furthermore, as we enter 2025, businesses, hobbyists, and professionals must stay informed about the top dual extruder options available.

The best dual-color 3D printer models now feature independent dual extruder systems, catering to both professional and amateur users. This guide examines eight outstanding dual extruder printers currently available, helping you make an informed decision based on your specific needs and budget.

New to dual extruder printing? Start with the right foundation by choosing professional 3D modeling software that supports multi-material design workflows.

Types of Dual Extruder 3D Printers

When selecting the best dual extruder 3D printer, understanding different configurations helps identify the system that best suits your specific printing needs, whether you prioritize material versatility, production efficiency, or creative flexibility in multi-material applications.

1. Independent Dual Extruder (IDEX)

IDEX systems feature two completely separate printheads that move independently along the X-axis. This configuration eliminates cross-contamination between materials, enabling unique printing modes like duplication and mirror printing for enhanced productivity.

Independent operation allows one extruder to remain entirely out of the way during single-material sections, preventing oozing and dripping. Premium models, such as the BCN3D EPSILON W50 SC, showcase how IDEX technology maximizes print quality and manufacturing throughput.

2. Single-nozzle dual extrusion

Single-nozzle systems merge two filament streams through a single nozzle exit point, making it impossible to achieve accurate color mixing and gradient effects with separate nozzles. This approach reduces mechanical complexity while maintaining dual-material capabilities.

Key advantages include:

- Seamless color blending and gradient transitions

- Reduced nozzle height differences and calibration issues

- Compact mechanical design with fewer moving parts

However, material switching requires purging between colors, increasing waste and print time. Models like the Geeetech A10M demonstrate how affordable single-nozzle systems make dual-material printing accessible to budget-conscious users.

Limitations include:

- Material waste during color changes

- Longer transition times between different materials

- Limited compatibility with vastly different material types

Color mixing capabilities often produce stunning visual effects, particularly for artistic prints requiring smooth transitions. The technology performs optimally when materials have similar printing temperatures and flow characteristics.

3. Swappable tool head systems

Swappable systems enable quick and easy hotend changes between different nozzle sizes, temperatures, and material configurations. This modular approach offers maximum versatility without requiring the installation of permanent dual-extruder hardware on every machine.

Professional models, such as the Raise3D Pro3, feature tool-free hotend swapping, enabling rapid configuration changes. This flexibility proves invaluable for production environments requiring frequent material transitions and specialized nozzle configurations.

Key Features to Look For

Evaluating essential specifications ensures your best dual extruder 3D printer investment delivers reliable performance, material compatibility, and ease of operation for both current projects and future printing requirements.

1. Build volume and print speed.

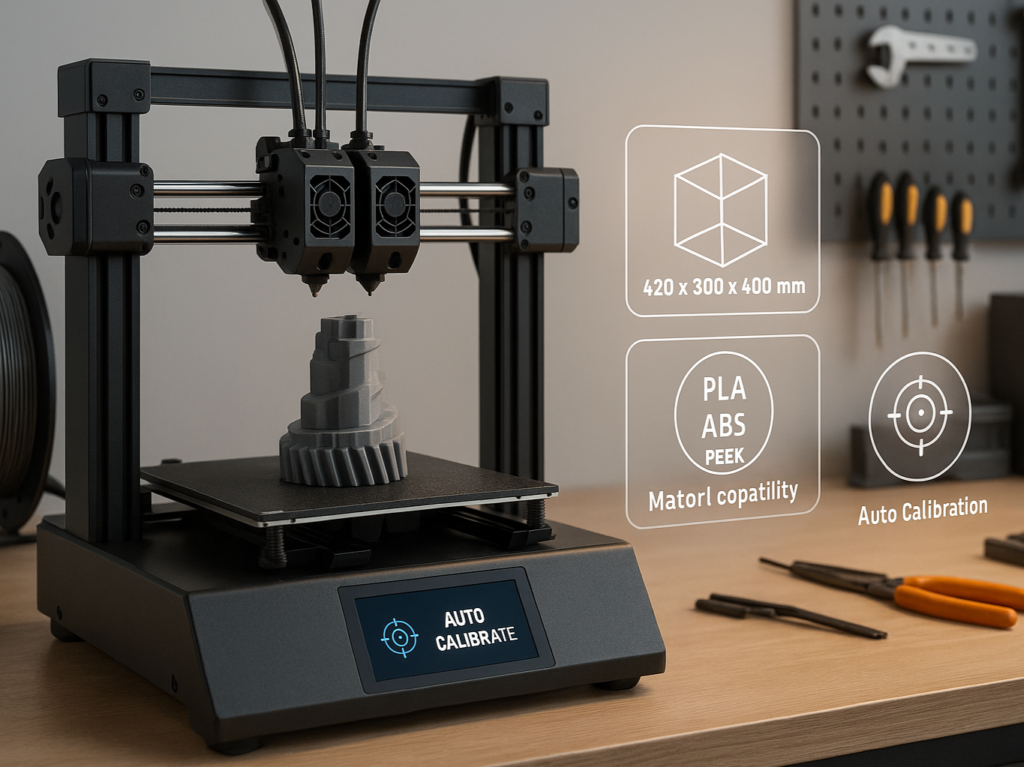

Build volume significantly impacts project possibilities, as larger chambers can simultaneously accommodate larger parts or multiple smaller components. Professional models, such as the EPSILON W50 SC, offer a 420 x 300 x 400mm workspace for substantial manufacturing capabilities.

Print speed in dual extruder systems depends heavily on material switching frequency and purging requirements. IDEX configurations often maintain faster speeds since inactive extruders don’t interfere with active printing zones, reducing job completion times.

Consider how dual extruder modes affect usable build volume, as some configurations reduce available space. Mirror and duplication printing modes require dividing the build platform, effectively halving the workspace for individual part dimensions.

2. Material compatibility

Temperature capabilities determine the compatible material ranges, with high-end systems reaching 300-350°C for engineering plastics such as PEEK and PEI. Entry-level models typically max out at 240-260°C, limiting options to standard materials like PLA, ABS, and PETG.

Heated chambers prove essential for advanced materials that are prone to warping, with enclosed systems maintaining stable temperatures throughout long print jobs. The FUNMAT PRO 310’s 100°C chamber exemplifies how environmental control enables successful printing with challenging engineering-grade materials.

Need professional 3D models optimized for dual extruder printing? Learn about 3D product modeling services that create multi-material designs perfect for your new dual extruder system.

3. Ease of calibration and maintenance

Modern dual extruder systems increasingly feature automatic calibration routines that eliminate tedious manual adjustments between nozzles. Advanced bed leveling sensors and Z-offset compensation reduce setup time, ensuring consistent first-layer adhesion across the entire build surface.

Key maintenance features include:

- Automatic nozzle height calibration between extruders

- Self-cleaning or anti-ooze mechanisms for inactive nozzles

- Accessible hotend components for routine cleaning and replacement

- Clear visual indicators for filament status and system alerts

Modular designs simplify component replacement and upgrades, while integrated monitoring systems provide real-time feedback on printer status. Professional models often include remote monitoring capabilities, allowing for oversight of extended production runs without the need for constant physical presence.

8 Best Dual Extruder 3D Printers in 2025

Selecting the best dual extruder 3D printer depends on your needs, whether for professional-grade engineering prints or creative multi-color projects. This section highlights eight top models of 2025, helping you compare features, performance, and value for your next 3D printing investment.

1. BCN3D EPSILON W50 SC

The BCN3D EPSILON W50 SC is a professional-grade powerhouse in dual-extruder 3D printers. This machine represents the pinnacle of what’s possible with current extrusion technology, particularly for those seeking industrial-level performance with exceptional material versatility.

(i) Build volume and IDEX system.

At the heart of what makes the EPSILON W50 one of the best dual extruder 3D printers available is its massive build volume of 420 x 300 x 400 mm. This generous workspace allows you to create extensive parts or multiple smaller components simultaneously, a game-changer for production environments.

The printer’s Independent Dual Extruder (IDEX) system sets it apart from conventional dual extrusion machines. Unlike standard dual extruders, where both heads move together, EPSILON’s extruders operate independently, providing several distinct advantages. During multi-material printing, one head actively prints. At the same time, the other remains entirely out of the way, eliminating common issues like material contamination or dripping onto your print.

Moreover, this IDEX configuration enables two particularly valuable printing modes:

- Duplication Mode: Both tool heads work side-by-side to create identical parts simultaneously, effectively doubling your production output

- Mirror Mode: Print matching opposite parts in a single job, ideal for symmetrical components like brackets, cases, or parts that need to fit together

This independent operation makes the EPSILON W50 an excellent choice for those considering the best IDEX 3D printer for production environments where throughput matters.

Material compatibility and chamber control

The EPSILON W50 SC is potentially the best multi-filament 3D printer due to its impressive material versatility. Its open filament system accommodates all 2.85mm materials, including:

- Standard filaments: PLA, PET-G, TPU 98A

- Support materials: PVA, BVOH

- Engineering materials: ABS, PP, PA

- Advanced composites: PP GF30 (30% glass fiber), PAHT CF15 (15% carbon fiber), PET CF15

- Metal filaments: Ultrafuse 316L, Ultrafuse 17-4 PH (with Hotend M)

The printer’s environmental controls are equally impressive. Its fully enclosed, passively heated chamber can reach temperatures up to 60°C, while the heated bed operates at temperatures up to 120°C. These features aren’t merely specifications but are essential for successfully printing with technical materials that would warp or fail in less controlled environments.

The “SC” in the model name also refers to the included Smart Cabinet, which integrates seamlessly with the printer. This cabinet provides humidity control to keep your filaments in optimal condition, preventing moisture absorption that commonly degrades print quality. The cabinet can store up to six 1kg spools and includes an uninterruptible power supply that protects your prints during power outages, a crucial feature for long, complex jobs.

(ii) Ideal use cases and pricing

The EPSILON W50 SC is particularly well-suited for professional and industrial applications. Its combination of large build volume, material versatility, and reliability makes it ideal for:

- Manufacturing environments requiring batch production of end-use parts

- Engineering teams working with advanced composite materials

- Product development requiring multi-material or dual-color prototypes

- Educational institutions teaching advanced manufacturing techniques

The EPSILON delivers exceptional results with minimal maintenance headaches for professionals seeking the best dual-color 3D printer with industrial capabilities. The machine’s robust construction and sealed chamber design ensure consistent print quality even with challenging materials.

- Price: Approximately $ 8,056 + VAT, with an additional cost for the Smart Cabinet.

- Investment: Significant, but offers a tangible return on investment.

- Productivity Gains: Doubles output with duplication mode, ensuring reliable operation even in unattended scenarios.

- Beneficiaries: Businesses and institutions.

The BCN3D EPSILON W50 SC is a complete professional printing solution rather than just a dual-extruder 3D printer. Its industrial-grade performance, material versatility, and productivity features justify its position among the elite options for serious users seeking the best possible results from multi-material and dual-color printing applications.

Don’t have the budget for your dual extruder printer? Discover professional dual extruder 3D printing services from top-rated digital agencies that can handle your multi-material projects.

2. FUNMAT PRO 310 by INTAMSYS

Engineered specifically for professional applications, the FUNMAT PRO 310 by INTAMSYS brings advanced IDEX technology to those working with demanding engineering-grade materials. This sophisticated dual-extruder 3D printer strikes a balance between precision, versatility, and thermal performance in a package designed for harsh manufacturing environments.

(i) Independent dual extruder (IDEX) benefits

The FUNMAT PRO 310’s standout feature is its Independent Dual Extruder (IDEX) system, allowing the two printheads to operate independently along the same axis. This advanced configuration offers significant advantages over conventional dual extruder setups, primarily through its versatile printing modes:

- Dual material printing: Combine different materials in a single print for complex geometries

- Mirror printing: Create symmetrical parts simultaneously, enhancing productivity

- Copy printing: Produce identical duplicates in a single job, effectively doubling the output

- Support material printing: Utilize specialized support materials for complex structures

Indeed, the IDEX system excels when printing intricate geometries. The independent operation ensures that while one extruder is actively printing, the other remains entirely out of the way, preventing common issues like material contamination or dripping. The FUNMAT PRO 310 is an excellent choice if you’re searching for the best IDEX 3D printer for complex industrial applications.

The printer’s build volume adapts based on your printing needs, offering 305 x 260 x 260mm when using a single nozzle and 260 x 260 x 260mm in dual nozzle mode. Consequently, you gain flexibility without sacrificing performance, making it suitable for a wide range of part sizes.

(ii) Heated chamber and mesh leveling

Temperature control represents another area where the FUNMAT PRO 310 distinguishes itself among the best dual extruder 3D printers. The system features a fully enclosed, actively heated thermostatic build chamber capable of reaching temperatures up to 100°C. This controlled environment proves crucial for maintaining low internal stresses and ensuring proper interlayer bonding, especially when working with engineering plastics.

- The build plate can reach temperatures of up to 160°C.

- The nozzle operates at temperatures of up to 300-350°C (model-dependent).

- High-temperature capabilities and excellent thermal insulation (thickened insulation layer, temperature-resistant cover) prevent warping or delamination of advanced materials.

In addition to its thermal performance, the FUNMAT PRO 310 features an advanced auto mesh leveling system with 100-point surface flatness measurement and automatic Z-axis compensation. This precision ensures consistent first-layer adhesion across the entire build surface, which is critical for successful prints with demanding materials. The system also features a flexible build plate for effortless part removal, eliminating the need for adhesives, and a glue-free bed adhesion.

(iii) Best suited for engineering-grade materials

The FUNMAT PRO 310 is the ideal multi-filament 3D printer for industrial applications due to its exceptional compatibility with engineering-grade materials. The printer’s thermal design addresses the challenges of printing high-performance polymers, enabling improved Z-direction tensile strength and enhanced mechanical properties.

The system excels with an impressive range of materials, including:

PC, ABS-HS, PPA-CF/GF, PA, PPS, ASA, HIPS, PA12-CF, PA6/66, PA6-CF, PC-ABS, PC-FR, PLA, and specialized support materials. Specific configurations are available for businesses requiring even more advanced materials support, including PEEK, PEEK-CF, PEEK-GF, PEI 1010, PEI 9085, and PEKK.

This material’s versatility proves particularly valuable for industries that require high-performance parts. For instance, the printer’s compatibility with PC-FR (with flame retardant properties) makes it suitable for rail transportation applications. At the same time, its ability to handle PC-ABS allows for long-term outdoor automotive applications.

- A high-temperature chamber benefits printing engineering materials like PCs, allowing for the printing of full-size PC parts (with edges exceeding 150mm) without warping, delamination, or deformation.

- Using properly dried filament prevents warping, bubbles, and burrs, ensuring continuous, high-quality printing of moisture-absorbent materials, such as nylon (PA, PA-CF).

The FUNMAT PRO 310 represents an excellent investment for businesses and professionals working with demanding applications where material performance and print reliability are non-negotiable requirements. For anyone considering the best dual-color 3D printer options with advanced engineering capabilities, this machine deserves serious consideration for its blend of versatility, precision, and thermal performance.

3. Flashforge Creator Pro 2

For those seeking entry into dual extrusion technology, the Flashforge Creator Pro 2 delivers IDEX capabilities at a fraction of the cost of industrial models. This compact printer strikes a balance between affordability and performance, making it an attractive option for both hobbyists and professionals on a budget.

(i) Affordable IDEX setup

In contrast to the higher-end printers discussed earlier, the Flashforge Creator Pro 2 introduces IDEX technology at a more accessible price point of $899. It is one of the most affordable ways to experience independent dual extrusion without compromising core functionality.

The Creator Pro 2’s standout feature is undoubtedly its Independent Dual Extruder (IDEX) system. As an upgrade to the original Creator Pro, this system solves many common issues in traditional dual extruder setups. By housing each nozzle in its printhead, the system effectively reduces problems with leveling, clogging, and oozing.

This IDEX configuration unlocks several valuable printing modes:

- Mirror Mode: Creates symmetrical objects simultaneously, ideal for parts that need to fit together

- Duplicate Mode: Doubles your productivity by printing identical models at the same time

- Multi-Material Mode: Combines different materials in a single print

- Soluble Support Mode: Uses water-soluble supports for complex geometries

Surprisingly, the printer features two metal scrapers on either end of the X-axis rod, which function as anti-oozing plates. These scrapers remove any filament that might accumulate at the hot ends, preventing the inactive nozzle from ruining your print. This thoughtful design feature helps maintain print quality despite the printer’s budget-friendly price.

(ii) Compact design and print quality

The Creator Pro 2 features a classic metal frame structure that provides stability during printing operations. Its fully enclosed design includes a removable acrylic cover and a closable front door with magnets. Consequently, this enclosed printing chamber significantly reduces the environmental impact on print results. It proves particularly beneficial when working with temperature-sensitive materials, such as ABS.

Both hotends can reach temperatures of up to 240°C and are powered by direct drive extruders housed within the printheads. The heated aluminum build plate reaches 120°C. It provides excellent adhesion, sometimes to the point of being too strong, as users note that prints adhere too tightly to the surface.

Despite its affordability, the Creator Pro 2 delivers remarkable print quality. Numerous reviews highlight how users achieve high-quality prints immediately, particularly when working with PLA and water-soluble PVA supports. Besides being compatible with Flashforge’s materials, the printer also accommodates third-party filaments, giving users flexibility in their material choices.

The 3.5-inch color touchscreen interface further enhances usability by making operations visible and displaying print status in real time. Additionally, the printer supports semi-automatic extruder calibration, making setup relatively straightforward for beginners.

(iii) Limitations in build volume

Admittedly, the Creator Pro 2’s build volume represents its most significant limitation. At 200 x 148 x 150mm, it offers roughly half the volume of some competitors. Furthermore, this modest build volume shrinks to approximately 95 x 148 x 150 mm when using specific dual extruder modes, such as mirror printing.

Another notable drawback is the non-removable build plate. This design choice makes removing completed prints somewhat challenging, especially given the strong adhesion of the BuildTak-type adhesive sticker covering the aluminum plate. As a result, the print surface tends to deteriorate more quickly than removable alternatives.

In the event of power outages, the printer also lacks features commonly found in modern machines, such as Wi-Fi connectivity and print resume functionality. Instead of a USB port, it uses an SD card slot for file transfers, which some users find less convenient.

The Flashforge Creator Pro 2 is an excellent value proposition for those exploring dual extrusion without a hefty investment. Its IDEX technology, enclosed build chamber, and reliable performance make it one of the best dual extruder 3D printers for budget-conscious buyers seeking quality dual-color or multi-material prints.

4. Geeetech A10M

Among budget-friendly options in the dual extrusion market, the Geeetech A10M takes a unique approach by utilizing color-mixing capabilities rather than employing independent printheads. This affordable printer bridges the gap between basic single-extruder models and more expensive dual-extruder systems, making it an intriguing option for hobbyists and tinkerers.

(i) Multi-color printing modes

The Geeetech A10M features a distinctive “2-in-1-out” design that enables actual color mixing through a single nozzle. Unlike traditional dual-extruder 3D printers using separate nozzles, this system feeds two filaments through a single 0.4mm brass nozzle. This design allows for several interesting printing modes:

The star feature is undoubtedly the Color Mixer software developed by Geeetech. This free, user-friendly tool allows you to create customized color gradients by importing your single-color G-code files and specifying mixing ratios. You can make thousands of mixing combinations by setting different start and end layers and specific percentages for each extruder.

- When the color mixing works correctly, the results can be impressive.

- The system excels particularly with gradients, allowing you to slowly fade from one color at the bottom to another at the top.

- You can control these gradients directly through the printer’s control panel, eliminating the need for a complex slicer setup.

However, the color mixing isn’t always perfect. The “mixing” typically results in half the extrusion width showing one color and half showing the other, rather than creating a truly blended filament. Admittedly, this effect creates an interesting visual dynamic where the print appears different depending on the viewing angle.

Ready to design your dual-material models? Explore the best 3D modeling software specifically chosen for creating printable designs with multiple materials and colors.

(ii) Open-source customization options

The Geeetech A10M offers substantial customization opportunities for those who enjoy tinkering. The printer runs on an open-source GT2560 control board, providing unlimited space for firmware modifications. This open architecture makes it particularly appealing for makers experimenting with different settings and capabilities.

The modular design extends throughout the printer’s construction. Key features include:

- Modularized extruder wiring for easy cable exchange

- Extruder cover with 360° ventilation design to enhance heat dissipation

- Extruder motor with a 3:1 gear ratio to amplify torque

- Silicon carbide glass printing platform for improved first-layer adhesion

Beyond hardware, the A10M is compatible with most common open-source slicers. Furthermore, enthusiasts have developed modified firmware versions, such as Marlin 2.0. x adaptations for this printer, expanding its capabilities beyond factory settings.

The printer also supports several optional upgrades, including a BLTouch/3DTouch auto-bed leveling sensor and compatibility with OctoPrint via a Raspberry Pi setup. These additions can significantly enhance the printing experience, albeit with additional investment.

(iii) Budget-friendly entry point

With a price of just $239, the Geeetech A10M represents one of the most affordable entries into dual extrusion 3D printing. This price point makes it particularly attractive for hobbyists who want to experiment with multi-color or multi-material printing without a significant financial commitment.

The printer offers reasonable specifications for its price bracket, including a build volume of 220 x 220 x 260mm. It supports a wide range of materials, including ABS, PLA, flexible PLA, wood polymer, PVA, HIPS, and PETG. However, complex engineering materials remain beyond their capabilities.

Practical features, such as filament run-out detection and power loss recovery, further enhance its value proposition. These quality-of-life improvements help prevent failed prints due to common issues, which is a thoughtful addition at this price point.

For those specifically interested in multi-color printing but constrained by budget, the A10M represents a viable alternative to more expensive dual extruder 3D printers. While it lacks the independent dual extruder systems of pricier models, its color-mixing approach offers unique creative possibilities that even more costly printers cannot match.

5. Bambu Lab P1S + AMS

The Bambu Lab P1S, with its Automatic Material System (AMS), represents a fresh approach to multi-material printing, emphasizing automation and ease of use. This innovative combination brings multi-color capabilities to an enclosed, compact printer that bridges the gap between hobby and professional-grade machines.

(i) AMS system for multi-material printing

At the heart of this printer’s appeal is the innovative AMS technology that distinguishes it from traditional dual extruder systems. Each AMS unit houses four filament slots, and up to four units can be connected in parallel, supporting an impressive 16-color printing setup. This modular approach lets you start with basic multi-material capabilities and expand as needed.

The AMS handles much more than just filament storage. Powered by a 32-bit MCU, sensor arrays, and intelligent algorithms, it intelligently manages:

- Automatic filament loading and unloading

- Filament tangle detection to prevent failed prints

- Seamless transitions between materials during printing

- Humidity control with a built-in sensor and desiccant compartment

Perhaps most impressively, the system offers automatic filament identification through RFID tags on Bambu Lab filaments. These tags communicate directly with Bambu Studio software to apply optimal print settings for each material. This feature makes the P1S an attractive option for hobbyists tired of manual calibration.

The AMS supports a wide range of materials, including PLA, ABS, ASA, PETG, PC, and more. Nevertheless, it’s worth noting that flexible materials like TPU aren’t compatible with the AMS due to jamming risks. When working with these materials, you must install spools directly on the rear holder.

(ii) Compact design and quiet operation

The P1S features a fully enclosed printing chamber that enhances print quality while containing noise. Compared to its predecessor (the P1P), the P1S includes a more comprehensive cooling solution with three specialized fans: an Auxiliary Part Cooling Fan for the prints, a Chamber Regulator Fan to maintain stable internal temperatures, and a Control Board Fan for electronics cooling.

When printing materials like ABS, an activated carbon filter effectively addresses odors and potentially harmful emissions. This consideration makes the printer suitable for home offices or shared workspaces where fume control is a concern.

Although fast printing typically generates noise, many users report that the P1S operates surprisingly quietly. One user mentioned being able to run both their P1S and another printer in a room with an open door while barely hearing anything from 16 feet away. Indeed, this experience varies depending on the print settings and the acoustics of your environment.

The machine’s welded steel chassis provides stability during high-speed operations. When paired with the AMS in the “P1S Combo” package, the system maintains a relatively compact footprint compared to some dual-extruder setups, making it suitable for environments where space efficiency is a priority.

(iii) Trade-offs in speed and build size

While the P1S offers remarkable multi-material capabilities, it comes with certain limitations. The print volume measures 256 cubic mm, which is relatively modest compared to market standards. This constraint becomes particularly noticeable when printing large models or multiple parts simultaneously.

Regarding print speed, the P1S leverages cutting-edge control algorithms with vibration compensation and pressure advance, enabling fast printing without sacrificing quality. Yet, these high speeds depend heavily on cooling, which occasionally leads to increased noise levels during intensive operations.

Although innovative, the AMS system itself introduces some trade-offs. Material waste accumulates when filament changes frequently during complex, multi-color prints (sometimes as many as 100 times). Accordingly, users should factor this additional material consumption into their calculations for larger projects.

- The P1S is not recommended for the direct printing of glass fiber or carbon fiber materials.

- An extruder and hotend upgrade is required for these materials.

- This limitation may disappoint users interested in working extensively with composite materials immediately.

Priced at approximately $849 for the combo package, including the AMS, the Bambu Lab P1S represents a middle ground between budget options and high-end professional machines. These trade-offs may be worthwhile for those prioritizing multi-material printing in a compact, enclosed system.

6. Ultimaker S7

The Ultimaker S7 exemplifies how dual extrusion technology can be refined for professional environments without sacrificing user accessibility. Known for its reliability in industrial settings, this printer strikes a balance between precision engineering and thoughtful design elements that address common printing challenges.

(i) Large build volume and material range

With a substantial build volume of 330 x 240 x 300 mm, the Ultimaker S7 provides ample space for creating larger prototypes or multiple smaller parts simultaneously. This generous workspace sets it apart from many competitors in its class. The printer truly shines with its material versatility, supporting over 280 different filaments. This extensive compatibility includes engineering grades, composites, and recycled materials, all rigorously tested for thousands of hours.

The printer features a dual-extrusion print head with swappable print cores, allowing you to switch between different nozzle sizes and material types quickly. This modular approach means you can configure the system for optimal performance across various applications:

- Type AA cores for build materials and Breakaway support

- Type BB cores for water-soluble PVA supports

- Type CC cores for composite materials

- Type DD cores for ceramic supports (with Metal Expansion Kit)

(ii) Air manager and enclosed chamber

The S7’s most significant improvement is its integrated Air Manager, which is independently tested to remove up to 95% of ultrafine particles during printing. Meanwhile, the fully enclosed build chamber, featuring a single glass door, enhances temperature stability, consistently improving print quality.

The printer also features a new PEI-coated, flexible build plate that dramatically improves first-layer adhesion, allowing for effortless part removal without the need for tools. Ultimaker reports that this innovation reduces print defects related to poor first-layer adhesion by approximately 50%.

(iii) Professional-grade performance

Beyond its basic functionality, the S7 incorporates several professional-grade features that justify its position among the best dual-extruder 3D printers. The system features an inductive sensor for more precise bed leveling and automatic tilt compensation, eliminating the need for manual calibration.

Connectivity options include both 2.4 GHz and 5 GHz Wi-Fi compatibility, which provides more reliable wireless connections, particularly valuable in environments with network restrictions. The printer also features an enhanced camera with improved resolution and a wider viewing angle, providing better remote monitoring capabilities.

For businesses seeking maximum uptime, the S7 can be paired with the Material Station, which allows for pre-loading up to six material spools and features automatic switching capabilities. This integration creates a comprehensive printing ecosystem designed for continuous operation with minimal intervention.

Planning to use your dual extruder printer for product development? Discover how professional 3D product modeling can transform your prototyping workflow and online sales.

7. Raise3D Pro3

The Raise3D Pro3 is a robust workhorse designed for manufacturing environments where reliability and versatility are paramount. With its industrial-grade construction and innovative features, this printer addresses common pain points in professional 3D printing workflows.

(i) Swappable print heads and remote monitoring

Raise3D’s innovative modular hotend system represents a key advancement for busy production environments. The interchangeable hotends feature a click-and-lock mechanism requiring no specialized tools, allowing users to swap components in seconds once the filament has been unloaded. This design dramatically reduces downtime during maintenance or when switching between material types.

Remote Monitoring (RaiseCloud):

- Cloud-based management solution.

- Real-time observation of all printer parameters (extruder/bed temperatures, remaining filament, general progress).

- Available as desktop software and mobile apps (Android, iOS).

- Provides production teams with constant visibility into printing operations.

The embedded webcam sends images approximately every five seconds, enabling semi-live print observation from anywhere. Hence, operators can verify print progress remotely without needing to inspect the machine physically.

(ii) High-temperature nozzle and large build area

The Pro3 features a maximum nozzle temperature of 300°C, enabling compatibility with an extensive range of materials, including engineering-grade filaments. Users can print with a variety of materials, including PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, Nylon, and various composite materials such as glass fiber, carbon fiber, metal fills, and wood fills.

The build volume adjusts based on the printing configuration. The single extruder mode provides a 300 × 300 mm area. In contrast, the dual extruder mode offers a volume of 255 × 300 × 300 mm. Similarly, the Pro3 Plus model extends the height to 605 mm while maintaining the same footprint.

(iii) Industrial reliability and cost

The Pro3, primarily designed for manufacturing applications, includes several reliability-focused features. The power recovery function resumes printing after outages, requiring only time to reheat components to operational temperatures. Likewise, safety sensors on all doors automatically pause printing when the doors are opened.

Environmental considerations haven’t been overlooked. The Air Flow Manager with HEPA filtration removes particles and odors while regulating chamber heat, creating safer working conditions in shared spaces.

Priced at approximately $ 5,599 for the standard model and $ 7,599 for the Pro3 Plus, this printer represents a significant investment, justified by its production capabilities. Given its robust all-metal frame, high-temperature performance, and remote management features, the Raise3D Pro3 is an excellent choice for businesses requiring the Best dual extruder 3D printer for small-batch production and functional prototyping.

Working on architectural projects? While dual extruders excel at creating multi-material models, consider specialized 3D printers designed for architectural models that may better suit your specific building design needs.

8. Zortrax M300 Dual

Polish manufacturer Zortrax delivers impressive dual-extrusion capabilities with the M300 Dual. This desktop 3D printer boasts industrial-grade print quality despite its relatively compact footprint. This printer stands apart from competitors with its specialized features for producing intricate, functional components.

(i) Dual-extrusion LDP Plus technology

The M300 Dual uses Layer Plastic Deposition Plus (LPD Plus) technology, which enables precise deposition of two separate filaments to create accurate representations of digital models. The system features two complete sets of components, each marked with either “A” for model material or “B” for support material, that can work interchangeably during printing.

This configuration enables extraordinary flexibility in printing complex geometries or moving mechanisms with supports in areas that would otherwise be inaccessible.

This printer’s ability to function in single and dual-extrusion modes makes it particularly valuable. Post-processing becomes remarkably straightforward when using water-soluble support material, as supports dissolve away. The build volume measures 265 x 265 x 300 mm (10.4 x 10.4 x 11.8 inches), providing ample space for large-scale projects.

(ii) Blackout system and video monitoring

Initially, the M300 Dual impresses with its blackout detection system that automatically saves printing progress during power outages. Once power returns, the printer resumes from where it was interrupted. This practical feature substantially reduces wasted materials and failed prints.

Equally important, the printer incorporates an integrated live-view camera for continuous remote monitoring. With multiple connectivity options (Wi-Fi, USB, and Ethernet), users can create manufacturing clusters of various printers. The material jam detection system further enhances reliability by pausing printing whenever it detects nozzle clogs or tangled filaments.

(iii) Best for large, complex models

The M300 Dual excels primarily when producing complex geometries with intricate internal structures. Its dual-extrusion capabilities make it ideal for creating functional parts with clean surfaces and dimensionally accurate cavities. The printer supports various materials, including engineering-grade and specialized metallic powder filaments.

The Zortrax M300 Dual represents an excellent investment in print reliability and quality for businesses and professionals needing to produce functional prototypes with complex geometries.

Finding Your Ideal Dual Extruder 3D Printer

The best dual-extruder 3D printers have transformed creative possibilities for both professionals and hobbyists. Key buying factors include budget, print volume, temperature capabilities, and dual extrusion type. Whether exploring multi-color printing or engineering-grade materials, selecting the right model ensures optimal performance for your unique project requirements.

Budget plays a major role when comparing models. Industrial-grade printers like the BCN3D EPSILON W50 SC and INTAMSYS FUNMAT PRO 310 deliver top-tier performance for advanced applications. More affordable options, such as the Flashforge Creator Pro 2 and Geeetech A10M, still offer core dual extrusion features ideal for hobbyists and entry-level users.

Choosing the Best dual extruder 3D printer depends on balancing budget and technical needs. From user-friendly machines for beginners to advanced systems for experienced operators, these printers enable complex geometries, multi-material designs, and stunning multi-color results, pushing creative boundaries well into 2025 and beyond.

Before investing $ 5,000 or more in a dual extruder system, consider exploring professional 3D printing services that offer dual extruder capabilities without the upfront equipment costs.

![Best Dual Extruder 3D Printer for Multi-Material Printing [2025 Guide]](https://fiverrhacks.com/wp-content/uploads/2025/06/ChatGPT-Image-Jun-25-2025-08_49_07-PM.png)